Screen Printing vs. Embroidery: Which Lasts Longest? (The 2026 Guide to ROI)

- February 5, 2026

- 10:00 pm

Imagine pulling your favorite branded shirt from the dryer—only to find the logo cracking and peeling after just a few months. That sinking feeling? It’s a wake-up call for any business owner. A failing logo doesn’t just ruin the garment; it erodes customer trust and makes your brand look unreliable. Your custom apparel is a walking billboard—don’t let cheap customization turn it into a liability.

Smart buyers measure true value with Cost-per-Wear: total cost divided by uses over the item’s lifespan. A low upfront price means nothing if replacements come every few months. High-quality, durable customization saves money long-term. In this 2026 guide, we compare screen printing and embroidery head-to-head on longevity, ROI, and real-world performance.

Technical Foundations: Surface Bonding vs. Structural Integration

The Science of Screen Printing: A Chemical Bond

Screen printing relies on a chemical marriage between ink and fabric. Printers primarily use Plastisol ink for its durability and vibrant color. This ink contains PVC particles suspended in a liquid plasticizer. It sits on top of the garment fibers rather than soaking in.

The magic happens during the curing phase. The ink must reach $320°F$ to dry properly. This intense heat triggers a chemical reaction. The plastic molecules fuse into a solid film. Water-based inks work differently by soaking into the cotton threads. They offer a softer feel but still require precise heat to set. A poor cure leads to the dreaded peeling you see on cheap shirts.

The Mechanics of Embroidery: Structural Integration

Embroidery abandons chemistry for pure physics. This method uses high-speed needles to pull polyester thread through the cloth. The machine creates thousands of tiny stitches to build your logo. Each stitch anchors directly into the garment’s weave.

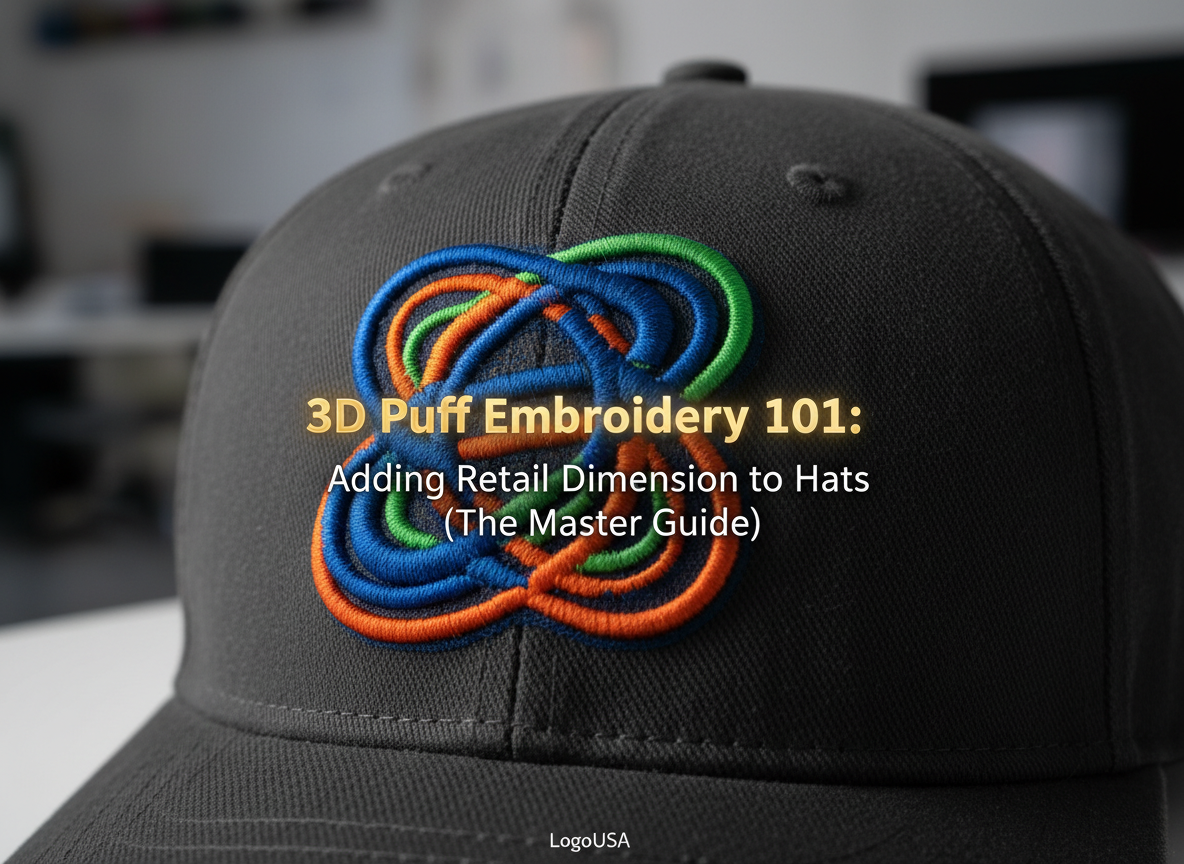

This process creates a Three-Dimensional effect that sits above the surface. You are not just laying color on the shirt. You are adding new material to the existing structure. This physical bond makes the design nearly impossible to remove. The thread becomes a permanent part of the fabric itself. It resists heat and friction better than any chemical bond.

The Wash-Cycle Battle: Survival of the Fittest

Your washing machine acts like a battlefield for custom apparel. Mechanical agitation stretches the fabric constantly. Detergents break the bonds that hold the design together. High dryer heat often finishes the job. These forces determine the true lifespan of your branded gear.

Stress Testing

We measure durability by how well designs handle repeated cycles. Every wash tests the decoration’s flexibility. Some methods thrive under pressure while others fail quickly.

Plastisol Cracking

Heat and motion eventually make screen print ink brittle. The ink layer loses its ability to stretch with the shirt. Small fissures appear across the logo’s surface. This cracking usually starts after twenty or thirty heavy washes.

Fibrillation

Fibrillation ruins the crisp look of a printed design. This happens when tiny fibers of fabric poke through the ink layer. The print looks faded or “fuzzy” even if the ink remains.

- Cause: Frequent rubbing during the wash cycle.

- Effect: A dull appearance on dark garments.

- Prevention: Use high-quality ringspun cotton.

Thread Fraying

Embroidery handles the wash cycle with much more grace. The polyester threads resist the chemical breakdown from laundry soaps. However, mechanical issues can still occur in rare cases.

| Issue | Description | Frequency |

| Thread Snags | Sharp objects catch a loop of thread. | Rare |

| Puckering | Fabric shrinks faster than the thread. | Moderate |

| Color Bleed | Poor-quality dyes run into the shirt. | Very Low |

Most embroidery outlasts the garment itself. You might see a loose thread after years of use. Trim the stray piece to keep the logo clean.

The Physics of Drape and Wearability

Longevity depends on more than just structural strength. A garment only provides value if a person actually wears it. Comfort dictates the true lifespan of any piece of clothing. If a shirt feels awkward, it sits in the closet forever.

Fabric Integrity and the Pucker Effect

Heavy embroidery can ruin thin, lightweight shirts. The dense stitching creates a heavy patch on a flimsy surface. This weight causes the surrounding fabric to sag and pull. We call this the pucker effect. It makes the garment look warped and unprofessional after one wash. Always match your stitch count to the weight of your fabric.

The Shield Effect in Screen Printing

Large screen prints create a “shield” across the chest. This solid layer of ink blocks all natural airflow. It traps heat against your skin, leading to excess sweating. Users often find these shirts uncomfortable in hot weather. A shirt that feels like a plastic sheet is quickly discarded.

- Breathability: Low for large solid prints.

- Flexibility: Decreases with increasing ink thickness.

- Comfort: Best for small logos or vintage textures.

Color Permanence: UV Resistance and Chemical Shields

Colors must stay vibrant to maintain brand standards. Faded logos look old and tired. Different decoration methods handle environmental stress in various ways.

Pigment vs. Polyester

Sunlight is a silent enemy of custom apparel. UV rays break the chemical bonds in screen-printing ink. This process leads to fading and discoloration over time. Embroidery uses polyester thread with built-in color fastness. These fibers retain their pigment even under direct sunlight.

Industrial Resistance

Many work environments require harsh cleaning chemicals. Industrial laundries often use bleach to sanitize garments. Screen print inks react poorly to these aggressive agents. Most embroidery uses Trilobal Polyester for superior strength. This specific thread resists bleach and maintains its luster.

Durability Ratings

| Feature | Screen Printing | Embroidery |

| UV Resistance | ⭐⭐⭐ | ⭐⭐⭐⭐⭐ |

| Bleach Resistance | ⭐ | ⭐⭐⭐⭐⭐ |

| Abrasion Resistance | ⭐⭐⭐ | ⭐⭐⭐⭐ |

Fabric Compatibility and Longevity Synergies

Choosing the wrong fabric ruins the best designs. You must match your decoration method to the material properties. This synergy ensures the garment lasts for years instead of weeks.

Material Science: Finding the Perfect Match

Fleece and high-pile fabrics present a unique challenge. These materials often absorb screen-printing ink. The liquid pigment sinks into the fuzzy fibers during curing. This results in a blurry or uneven logo.

Embroidery performs better on heavy, textured items, such as hoodies. The needles sit on top of the fleece nap. Conversely, embroidery fails on thin spandex or performance wear. The heavy stitches pull the stretchy fabric out of shape. This creates holes or permanent ripples in the garment.

Longevity Synergies

- Heavy Cotton (200+ GSM): Supports dense embroidery or thick ink.

- Lightweight Synthetics: Thrives with soft, water-based screen printing.

- Outerwear: Requires the structural strength of polyester thread.

The Psychological ROI: Perception of Authority

Longevity also exists in the mind of the wearer. People keep high-quality items and discard cheap ones. This choice reflects directly on your brand authority.

The Disposable Swag vs. Professional Uniform

Many companies give away cheap, printed shirts at events. These items often end up in the “T-shirt Drawer” for sleeping. They rarely see the light of day in public.

Embroidery creates a 3D texture that signals an established business. This professional look turns a simple shirt into a uniform. People feel more confident wearing embroidered gear to meetings. A logo with physical depth commands more respect than a flat print.

Brand Equity

Your logo represents your reputation. A peeling print suggests a lack of attention to detail. Embroidery maintains its crisp edges for the life of the shirt. This consistency builds long-term trust with your audience.

The Cost-Per-Wear Financial Model

Smart managers look past the initial invoice. They focus on the total cost over the garment’s life. This approach reveals the hidden trap of cheap apparel.

Shifting the Formula

A cheap printed shirt might cost ten dollars. A high-quality embroidered polo might cost twenty-five dollars. However, the printed shirt fails after ten washes. The embroidered polo lasts over 100 washes. The expensive item actually costs less per use.

The Real Math: 67% Savings Over Time

Quality gear saves your budget in the long run. You stop paying for shipping and setup fees every three months.

| Item Type | Initial Cost | Lifespan (Months) | Monthly Cost |

| Cheap Print | $12.00 | 4 | $3.00 |

| Premium Print | $18.00 | 12 | $1.50 |

| Embroidery | $25.00 | 24 | $1.04 |

Frequent replacements represent a hidden tax on your business. Invest in quality once to avoid paying for the same logo three times.

Environmental ROI: Sustainability through Durability

Durability serves as the strongest tool for environmental protection. A shirt that lasts longer stays out of the landfill. This longevity reduces your brand’s total carbon footprint.

Slow Fashion in 2026

Modern consumers value items with long lifespans. We call this movement “Slow Fashion.” Buying one high-quality item beats buying four cheap ones. This habit saves water and reduces manufacturing waste. Choosing embroidery or premium prints supports a healthier planet.

The Chemical Footprint

Screen printing involves several liquid chemicals and heavy metal pigments. These materials require careful disposal to protect local water supplies. Embroidery offers a “dry” decoration alternative. The process uses only needles and polyester thread. This method creates significantly less chemical runoff during production.

Industrial Resilience: Resistance to Abrasion and Chemicals

Hard labor puts extreme stress on every garment. Workers in the trades need gear that survives the job site. Standard decoration methods must withstand constant friction and grit.

Trade Industry Standards

Construction and automotive work expose shirts to grease and oil. These substances can bind to screen-print inks. Harsh scrubbing then pulls the ink away from the fabric. Metal shavings and rough surfaces also “sand down” printed graphics over time.

The Winner for Hard Labor

Embroidery wins the battle for industrial durability. The thick polyester thread resists abrasion from tools and equipment. It handles heavy-duty detergents better than any print. Mechanics and builders prefer embroidered logos for their rugged performance.

Care Guide: Extending the Life of Your LogoUSA Apparel

Proper maintenance can double the lifespan of your custom gear. Follow these steps to keep your LogoUSA products looking brand new.

- Wash your garments in cold water only.

- Turn every shirt inside out before cleaning.

- Avoid using an iron directly on printed logos.

- Skip the high-heat setting on your clothes dryer.

- Use mild detergents without harsh bleaching agents.

- Hang dry your items whenever the weather allows.

The Strategic Decision Matrix

Use this table to pick the right method for your project.

| Factor | Screen Printing | Embroidery |

| Production Speed | Very High | Moderate |

| Initial Price | Low | High |

| Durability | Moderate | Extreme |

| Best Use Case | T-shirts and Events | Polos and Outerwear |

Conclusion: Choosing Your Brand’s Legacy

The specific application always dictates the best decoration method. Screen printing offers unmatched speed and cost-efficiency for large events. Embroidery provides the professional authority required for long-term service and industrial uniforms. Both methods provide incredible value when matched to the correct fabric weight and GSM.

Ready to build your brand’s legacy with quality apparel that actually lasts? Visit LogoUSA to start your custom order today. Our experts will help you choose the perfect match for your next project.